What is a Three-Row Cross Roller Bearing?

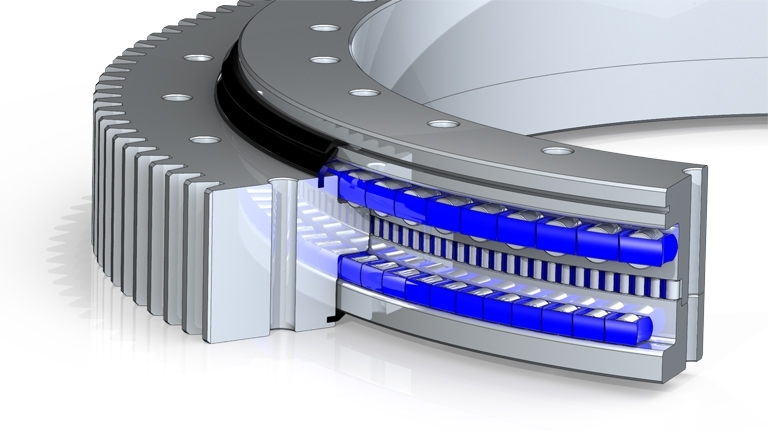

A three-row cross roller slewing ring with triple cylindrical roller arrangements goes beyond ball and single-row roller designs to provide the highest axial, radial, and overturning moment capacities. The upper and lower rows handle axial loads, while the middle row carries radial loads—thus distributing forces independently and minimizing contact stress. Available in Ø800–Ø5000 mm diameters with internal gear, external gear, or gearless versions.

These bearings are preferred in heavy crawler cranes, offshore trawl winches, wind turbine main slewing drive systems, steel mill table rotators, and mining equipment. A high-module gear profile (m ≥ 12) combined with heat-treated 42CrMo4 rings at 50–60 HRC ensures outstanding resistance to gear wear. Integrated lubrication channels and optional vibration-temperature sensor housings optimize maintenance intervals and reduce unplanned downtime.

Three-Row Roller Bearings

Bearing

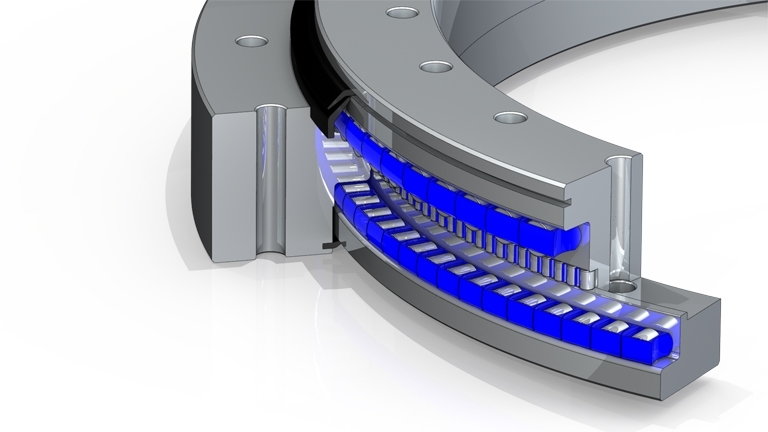

Three-row cross roller bearings without gears are designed to withstand very high axial and radial loads. These gearless types are often used in rotating tower systems and are ideal for applications not requiring a gear interface.

Reel Makina’s gearless three-row roller bearings provide quiet, safe, and precise rotation in welded drive systems, making them preferred solutions in defense, logistics, and industrial automation applications.

Internal Gear

Three-row cross roller bearings with internal gears provide high load transmission in compact systems. This design saves space and integrates motion directly into the inner structure, making it suitable for wind turbines, military vehicle turrets, and energy systems.

The enclosed gear configuration offers additional protection from external factors. Reel Makina ensures both high material quality and ease of assembly, delivering long-lasting performance under heavy use.

STANDART SERİ 3R20 İÇTEN DİŞLİ (Ø1397-Ø2147)

VIEWExternal Gear

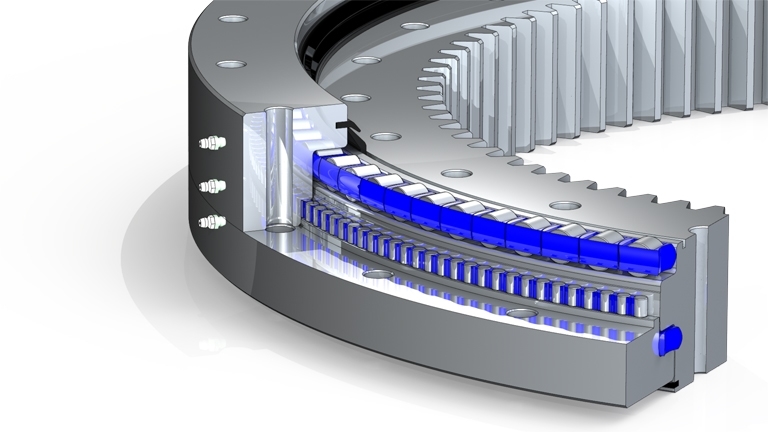

Three-row cross roller bearings with external gears deliver high torque transmission and modular assembly advantages. These bearings are commonly used in crane systems, offshore platforms, and heavy equipment carriers, allowing easy mechanical integration via the external gear profile.

Reel Makina’s external gear roller bearings are produced using high-quality surface grinding and precision milling, ensuring reliable operation in challenging fields from steel production plants to mining machinery.