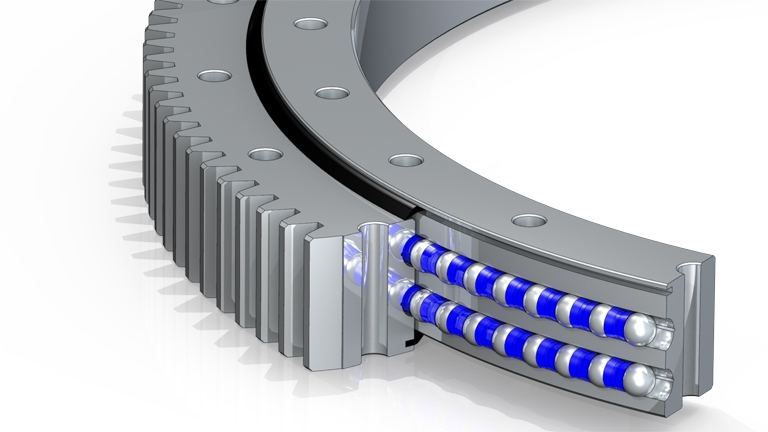

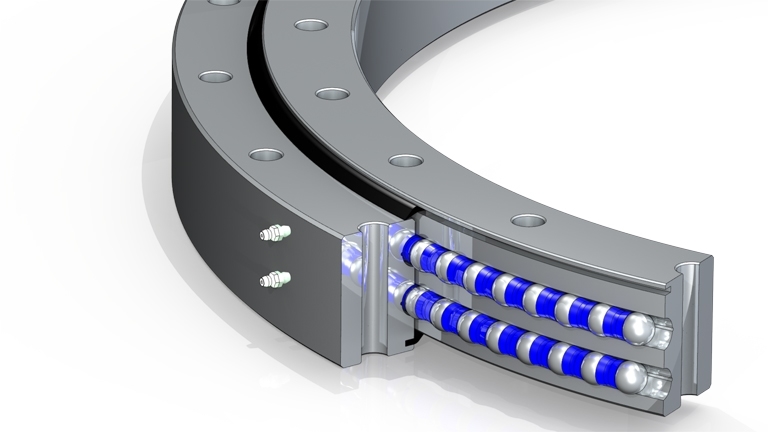

What is a Double-Row Ball Profile Bearing?

A Double-Row Ball Profile Slewing Ring offers up to 60% higher axial, radial, and moment load capacity compared to single-row designs, thanks to its two ball raceways. We manufacture them with external gear, internal gear, or gearless options in diameters ranging from Ø300 mm to Ø5000 mm. Increased rigidity enhances positional accuracy in heavy-duty applications from crane towers to wind turbine yaw systems, while the wider ball distribution reduces vibration for quieter operation. Compared to the single-row model, body height increases by approximately 15%, but maintenance intervals are longer, and fatigue life improves by over 25%. Internal/external gear options adapt to your drive design, and optional sensor housings facilitate integration of predictive maintenance systems.

Double-Row Ball Profile Bearings

Bearing

Ball Profile Bearings offer high load capacity, low friction, and long service life, making them indispensable in industrial systems. Bearings manufactured by Reel Makina deliver efficiency in CNC machines, conveyor systems, industrial robots, and slewing applications. Our bearing systems provide quiet operation, impact absorption, and easy maintenance to maximize machine performance.

At Reel Makina, we produce bearings with precise tolerances and to the highest quality standards. Every bearing undergoes 100% inspection and can be custom-produced up to Ø5000 mm. Trusted in numerous projects within the food, energy, defense, and automation industries, our products add strength and continuity to your operations.

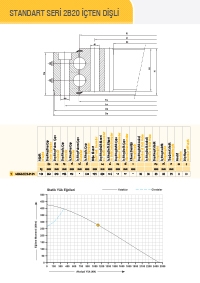

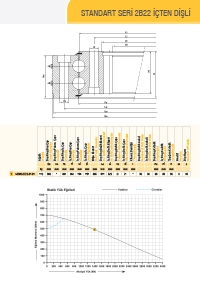

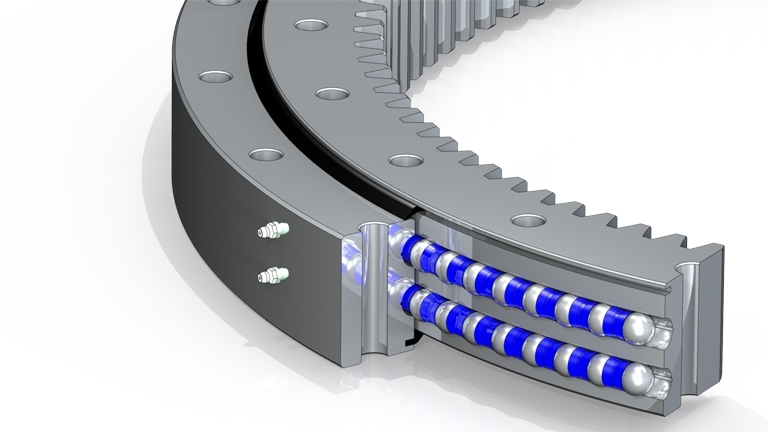

Internal Gear

Internal gear Slewing Rings stand out for their compact design in systems with limited outer space. Widely used in wind turbines, crane systems, tower platforms, and defense applications, internal gears ensure high torque transmission and secure positioning. Reel Makina’s internal gear solutions deliver durability and long-term performance.

Our internal gear bearings are manufactured with application-specific tooth profiles, low backlash tolerance, and precise heat treatment processes. Especially preferred in defense, tunnel boring machines, and marine projects, our products perform exceptionally under excessive load and harsh environmental conditions. They are provided with tailored technical support for every sector.

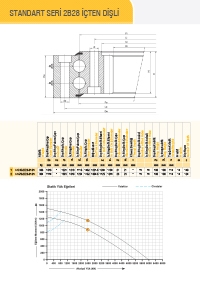

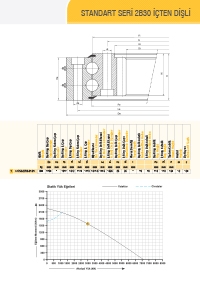

STANDART SERİ 2B20 İÇTEN DİŞLİ (Ø850)

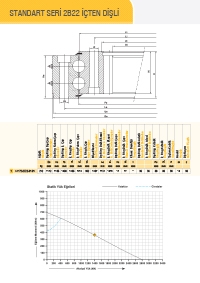

VIEWSTANDART SERİ 2B22 İÇTEN DİŞLİ (Ø982)

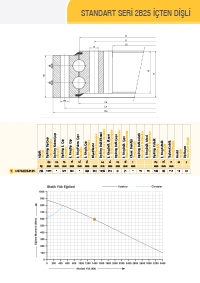

VIEWSTANDART SERİ 2B22 İÇTEN DİŞLİ (Ø1172)

VIEWSTANDART SERİ 2B25 İÇTEN DİŞLİ (Ø1074)

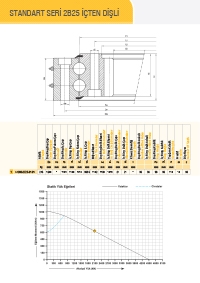

VIEWSTANDART SERİ 2B25 İÇTEN DİŞLİ (Ø1200)

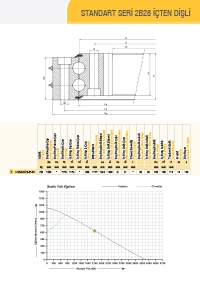

VIEWSTANDART SERİ 2B28 İÇTEN DİŞLİ (Ø1250)

VIEWSTANDART SERİ 2B28 İÇTEN DİŞLİ (Ø1345-Ø1470)

VIEWSTANDART SERİ 2B30 İÇTEN DİŞLİ (Ø1750)

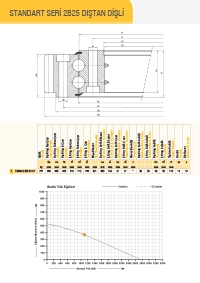

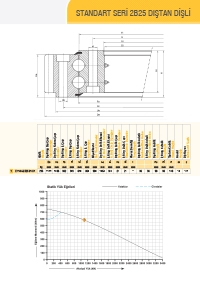

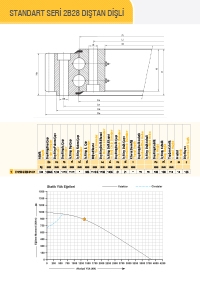

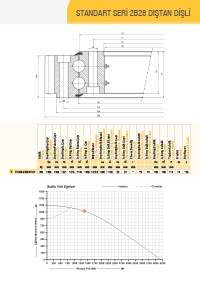

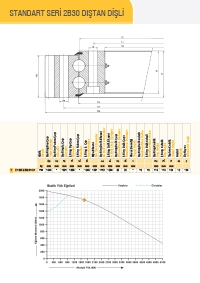

VIEWExternal Gear

External gear Slewing Rings offer high torque transmission and easy integration with external mechanisms in large-scale equipment. Frequently used in excavators, cranes, concrete pumps, and heavy industrial machinery, they deliver efficiency and robustness in operation. Reel Makina’s external gear bearings provide flawless solutions for heavy industrial loads.

Our external gear systems feature precisely milled tooth profiles and high surface hardness for long-lasting operation. With manufacturing precision beyond standard requirements, they serve a wide range of applications from port cranes to defense systems. Each bearing undergoes stringent quality control before delivery.