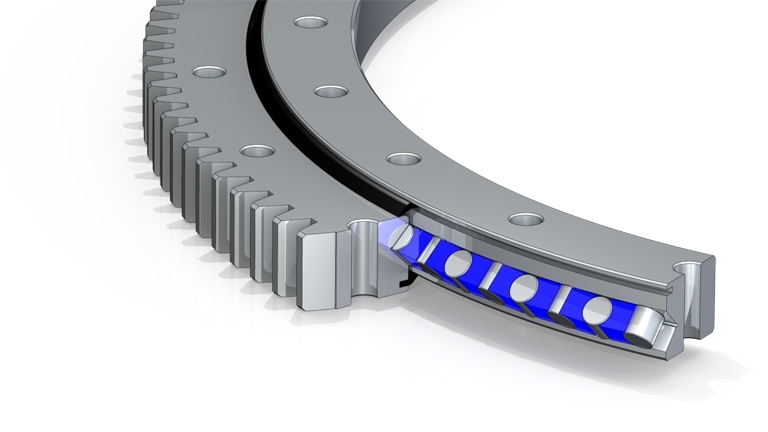

What is a Single-Row Cross Roller Bearing?

A Single-Row Cross Roller Slewing Ring replaces the single ball raceway with cylindrical rollers, increasing the contact surface and delivering up to twice the load-moment capacity of ball-type models. Standard diameters start at Ø300 mm – Ø2000 mm, with custom production up to Ø5000 mm available. Ideal for applications where high axial and radial forces as well as critical overturning moments are present—such as wind turbine yaw systems, crawler cranes, and foundry turntables. The roller arrangement lowers rolling resistance, while uniform heat distribution results in operating temperatures averaging 10°C lower than ball designs. Internal or external gear options with high module (m ≥ 10) tooth profiles reduce wear on the drive pinion. Heat-treated 42CrMo4 rings offer both 50–60 HRC surface hardness and impact toughness, with optional sensor housings for real-time vibration and temperature monitoring, enabling predictive maintenance.

Single-Row Cross Roller Bearings

Internal Gear

Internal gear cross roller bearings integrate torque transmission within the inner structure, saving space in systems with limited external dimensions. Preferred in welding machines, defense systems, radar platforms, and rotating turret mechanisms, they stand out for their compact design and high load capacity.

At Reel Makina, internal gear cross roller bearings are manufactured with high-precision tooth profiles and special coatings for corrosion resistance. Their low backlash tolerance and stability under load make them ideal for systems requiring precise positioning.

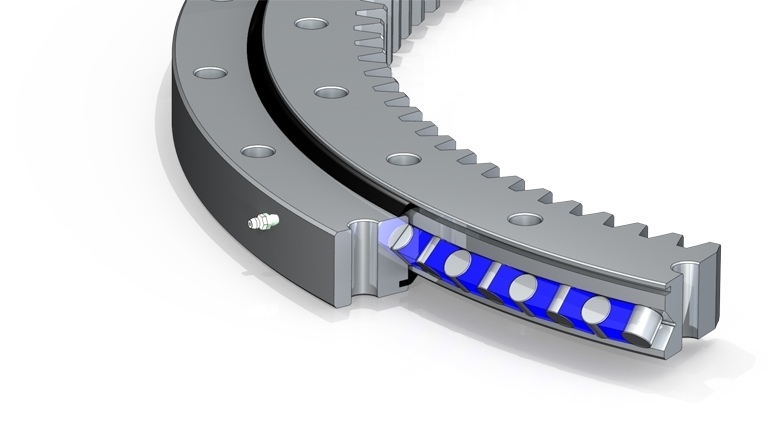

External Gear

External gear cross roller bearings are commonly used in high-torque applications such as large cranes, tower systems, and rotating platforms. Machining the gear onto the outer diameter provides easy installation and mechanical integration, ensuring flawless performance under heavy loads.

Reel Makina’s external gear cross roller bearings are specially developed for high surface hardness, low wear rate, and long-term operation. They stand out for their durability in energy, construction, steel production, and offshore applications.